Innovative Inventionl

No more knobs!

Simply Tighten the Panels in 30 Seconds!

Best Demountable Flood Panel Everl

[ Threshold ] .Bear weight of more than 80 tons without accumulate, also decrease the possibility of tripping hazard. |  |

| [ Anchoring Plate ] .Fixed on the wall to hook end posts. . It can be applied to all kinds of sites by different installation methods: downward. |

[ Middle Post ] .The same function as Side Post, only with tightening devices on both sides. .Required when the cover range needs to be widely extended. .With bases and brace: pressure. |  |

[ Back Support ] the flood panel. flood panel to resist current pressure. |  |

[ Watertight Panel ] that it won’t drop off in the future. bugs and cutting. up to 1300kg. |  |

[ Tightening Lock ]

.Put on the side post or middle post to

tighten the panels downward.

.Can be locked at the end of the assembly

process to prevent the theft of the flood

panel or the accessories.

[ Storage Rack ] .Types: Horizontal, Vertical or Hidden |  |

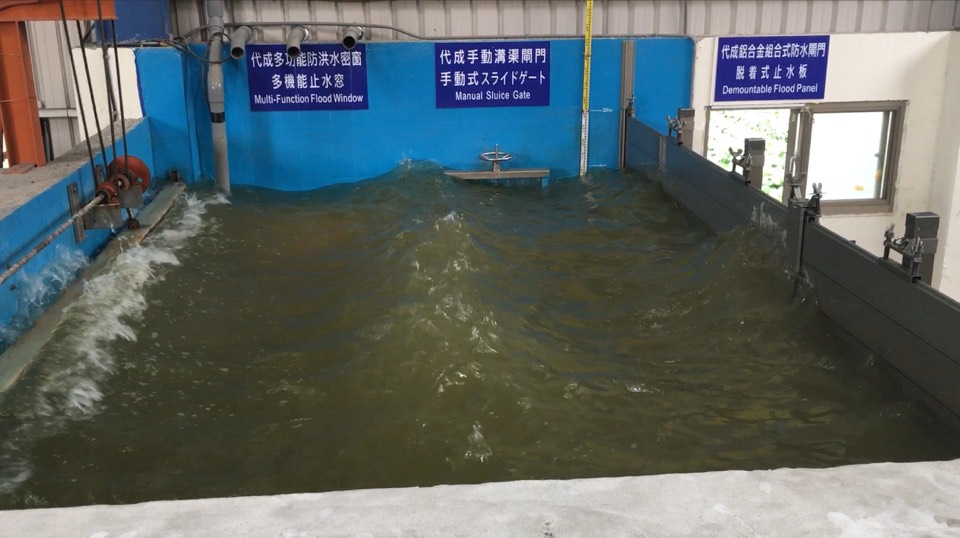

DCAM-02 has been tested according to

international testing standards- BSI standard.

Current leakage test

Wave leakage test

Static head leakage test

Obtained patents in Taiwan, EU, Japan, Thailand, Indonesia China and currently applying for international patents, the flood panel is easy to operate and the tightening process can even be finished in 30 seconds by a single individual. The flood-stopping performance of the flood panel is absolutely brilliant; and it has already been sold to the USA, Japan, Australia,

Thailand, Indonesia, Vietnam, Hong Kong and Macau.

DCAM-02 in Hong Kong

DCAM-02 in Hong Kong

DCAM-02 in Hong Kong

DCAM-02 in Indonesia

DCAM-02 in Macau

DCAM-02 in Macau

DCAM-02 in Macau

DCAM-02 in Macau

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Japan

DCAM-02 in Japan

DCAM-02 in Japan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan

DCAM-02 in Taiwan